Download Software The Steam Trap Handbook

Removing condensate and air from your system is essential. Returning condensate to the boiler house maximizes use of energy. Spiral Sarco the right steam trap for your application and the people to advise you.

A steam trap has two major functions: to remove condensate as quickly as it is formed, and to prevent steam discharge. There are certain installationfaults which negatively impact the ability for traps to effectively perform these functions efficiently.A high percentage of steam trap failures are simply due to incorrect installation.Proper installation should provide six years of maintenance-free operation. 16 Best Practices for steam trap installations are outlined here:1. The most important rule to remember for steam trap installation is GRAVITY. Condensate must flow from the process to the steam trap by the forces ofgravity. Pressure and velocity can’t be relied on to remove the condensate from the process.2. Determine the steam leak rate of the new steam traps that are being purchased per the following leak rate standards:a.

ISO 7841All steam traps leak a quantifiable amount of steam and the consumer should be specifying steam traps with the least amount of steam loss to preventunnecessary energy loss.3. Steam traps with 1 in. Or smaller connections should use tubing with tube connectors to eliminate leak points such as threaded connections.4.

There are steam component manufacturers that have tube connections available for steam trap installations. Ensure material pressure ratings areacceptable.5. Never reduce diameter of the tubing/piping before the steam trap or reduce connection size of the steam trap. Piping from the process to the steam trapshould always be equal to or larger than the process outlet connection. For example, a steam unit heater with a 1 in. Condensate outlet would require a 1in. Or larger tubing/piping from the unit heater to a same connection size on the steam trap.6.

Expand the tube/pipe diameter after the discharge connection of the steam trap. For example, a 1 in.

(connection) steam trap discharge tubing/pipingshould be increased to 1.25 in or 1.5 in.7. Steam traps with a connection size of 1 in. Or smaller should be connected to the tubing or piping with universal mounts. The universal mount providesthe ability to connect the steam trap to the application with two bolts, thus dramatically reducing the time for installation of a steam trap.8. Install a strainer as part of the installation of a steam trap. The strainer can be accomplished by the following:a. External strainer ahead of the steam trapb.

Steam trap with integral strainerc. Universal mount with an integral strainerThe use of a strainer will eliminate or reduce premature failures of steam trap due to corrosion.9. When installing an external or internal strainer always install a blow-off valve on the strainer. This allows the strainer to be blown down duringoperation, and permits the steam trap cavity to be safely depressurized during servicing.10.

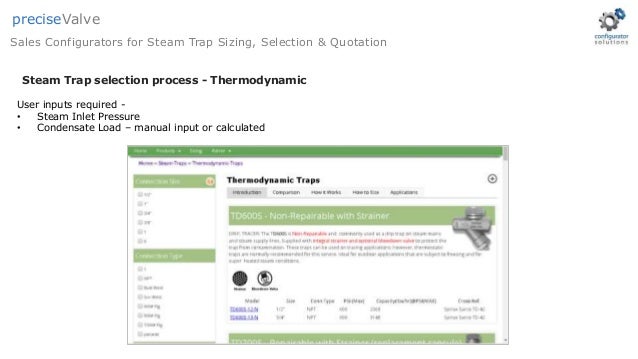

Always install the steam trap in a location that is accessible by plant personnel.11. Install a visual indication of the steam trap performance on all process applications. The visual indication can be a sight glass or test valve.12.

9, The Removewat is a WAT Remover tool to eliminate probably the most successful PC software Windows Activation Technologies in Windows 7 and Windows 8. Removewat is a tool for you to trigger your Microsoft Windows. It can activate Windows Vista, Windows 7 Professional, Windows 7. Removewat is activator for Microsoft Windows and Office Programs. Download activator Now. The tool is developed by group TeamDaz. One of the well-known Activator is Removewat 2.2.9, You can download Remove WAT for Microsoft Windows 7, Windows 10 and for Microsoft. Removewat 2.2.9 Full Working Activator For Windows 7, 8, 8.1 It might be Tiny in size, but an essential program made serve important purpose. Removewat 2.2 9. Removewat 2.2.9 Crack is an activator and used to activate windows. It is a program for pirated windows activation. It provides a marvelous full validation of the.

Yarway Steam Trap Catalog

Locate the steam trap below the lowest condensate discharge point of the equipment.13. Never install a rise in the pipe ahead of a steam trap.14.

Check valves should be installed after the steam traps in most applications.15. Develop and maintain installation standards for all applications.16. Material test reports on all components (steam traps, connection devices, etc.)b. B31.1 Piping codeor calltoday to prevent trap failure.